North India’s 1st “Iconic awarded” TMT/ Sariya Brand

Produced by - MAA SHEETLA VENTURES LTD

Product -

We are producing Fe 415D for commercial market as per BIS norms with CNC RiB pattern for dream houses of every Indian.

Fe 500 D for multi stories building, infrastructure projects, Roads, under the BIS licence & norms as well, everywhere in big projects…

Fe 550 D for giants infrastructural projects like dam, power projects, railways project & for seismic zone 5 or 6….

600 CRS TMT for various type of corrosion prone areas like coastal areas etc & for seismic zone 6 and above

Billets- 100x100 mm to 125x125 mm BIS approved billets

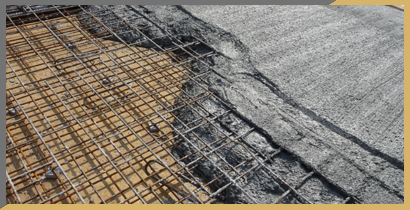

Best Bonding with Concrete :

Despite steel and concrete being two different materials, they should form as a single unit in a reinforced structure. This can happen only when the concrete grips the steel bars to form the strongest bond through unique rib pattern of MITTAL Thermax TMT bars which has a unique rib pattern of greater depth and closer rib spacing. These ribs are not man made but made with using the computer controlled CNC notch cutting machines. Ordinary manually made ribs will always leave the scope for non uniform and weaker bonding through out the structure. Because of this better bonding with concrete, MITTAL Thermax TMT bars make building strong and last for generations.

| Constituent | Fe 415 | Fe 415D | Fe 500 | Fe 500D | Fe 550 | Fe 550D | Fe 600 |

|---|---|---|---|---|---|---|---|

| Carbon (%MAX) | 0.30 | 0.25 | 0.30 | 0.25 | 0.30 | 0.25 | 0.30 |

| Sulphur (%MAX) | 0.060 | 0.045 | 0.055 | 0.040 | 0.055 | 0.040 | 0.040 |

| Phosphorus (%MAX) | 0.060 | 0.045 | 0.055 | 0.040 | 0.050 | 0.040 | 0.040 |

| S+P (%MAX) | 0.110 | 0.085 | 0.105 | 0.075 | 0.100 | 0.075 | 0.075 |

WELDABILITY :

MITTAL Thermax TMT bars have excellent weldabilty as they are superior and due to their low carbon equivalent. They can be butt-welded or lap-welded using ordinary rutile coated electrodes of matching strength. In manual arc welding no-pre warming or post-welding treatment is necessary.

BENDABILITY :

Tough outer surface and soft core of MITTAL Thermax TMT bars result in rebar with excellent bendability. These bars can be bent easily which results in lot of advantages during construction.

| - | Chemical Composition (MAX) | Mechanical Properties (MIN) | - | |||

|---|---|---|---|---|---|---|

| - | - | MITTAL TMT | - | BIS | MITTAL TMT | |

| %C | 0.25 | 0.25 | YS(N/mm2) | 500 | 530 | |

| %P | 0.040 | 0.040 | UTS(N/mm2) | 565 | 580 | |

| %S | 0.040 | 0.040 | UTS/YS Ratio | 1.10 | 1.118 | |

| %P+S | 0.075 | 0.070 | %Elogation | 16 | 18 | |

| CE* | 0.42 | 0.38 | %Uniform Elogation | 5 | 8 | |

SEISMIC RESISTANCE :

By virtue of its state of the art rolling process. MITTAL Thermax TMT bars offer a far greater resistance to any seismic pressure When compared to ordinary bars.

CORROSION RESISTANCE :

MITTAL Thermax TMT bars are produced by Thermo Mechanical treatment and not by cold twisting. Therefore there are no tensional residual stresses in the bar which results in superior corrosion resistance characteristics compared traditional cold twisted bars.

APPLICATIONS :

MITTAL Thermax TMT bars are available in various sizes viz. 8,10, 12, 16, 20, 25, 28 and 32 MM for all types of constructions like industrial, residential, infrastructure projects like roads, bridges, dams, sea ports and all types of multi storied structures. MITTAL Thermax TMT bars are available not only in the Northern India but also in the rest of India, Thanks to our efficient market and dealer network built over the years made MITTAL Thermax over the years made MITTAL Thermax over the years have made MITTAL Thermax TMT bars available to one and all.